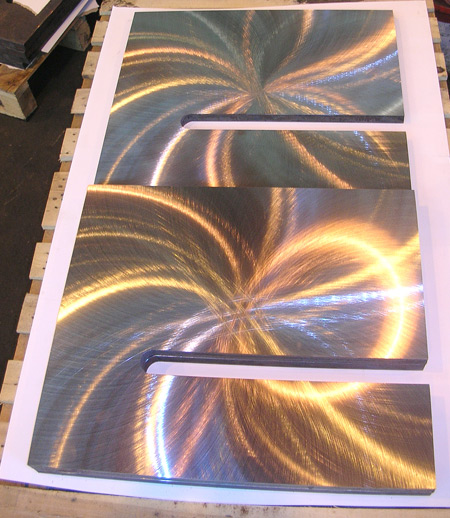

BLANCHARD GROUND FRAME PLATE BURNOUTS FOR PRINTING PRESS MANUFACTURER

Hamilton Precision, LLC, a division of Seilkop Industries, Inc. produced these frame plate burnouts with a featured slot for a customer in the printing press industry. Measuring 23-7/8” long, 20-5/8” wide, and 1-1/8” thick, each plate was burnt on our large burner (100″ X 50′ water table), deburred, sent to stress, and then ground on our 48” Blanchard grinder. We’re happy to provide or work with customer supplied materials, including A36, C1025, C1045, 4140, 4340, A572, and free machining steel. To provide faster turnaround, we always stock A36 plate from 1/4″ to 6 1/4″ – 96″ x 240″, and we’re pleased to offer an array of other services, such as milling, lathe work, and drilling. We hold tight grinding and horizontal tolerances. To learn more about this project, including our varied equipment, please see below.

BLANCHARD GROUND FRAME PLATE BURNOUTS PROJECT HIGHLIGHTS

| Capabilities/Processes |

Oxy-Fuel burned Deburred (all around) Stress Relieved |

Blanchard Ground Parallel Blanchard Ground Flat |

| Burn Contour |

1/32 Maximum irregularity at start of burn Corners: 90" +/- 1/16/FT |

Slots: 90" +/- 1/16/FT Ground to 1.00" |

| Thickness | Within +/- 0.002 | |

| Flatness | Within +/- 0.005 | |

| Parallel | Within +/- 0.001/FT | |

| Length | 23 7/8" | |

| Width | 20 5/8" | |

| Fractions | 1 7/8" | |

| Base Material (and inventory) |

A36 We can also work with (your materials or ours): C1025 C1045 4140 4340 |

A572 Free Machining Steel |

| Packaging | Pallet / Shrink Wrap | |

| Industry | Printing Press | |

| Drawing Type | DXF File | |

| Parts |

Oxy Fuel Burner (Burny 3 CNC Controlled):

|

Blanchard Grinder (Rotary Surface):

|

| Secondary Services |

Machining Milling Lathe |

Drilling Tapping |

| Delivery Location | Ohio |